Interested? Contact us to discuss your options

January 2026, no. 146

Figure 2: Illustration of bending moments and shears forces in the first global vertical flexural vibration mode.

Figure 1: Illustration of bending moments and shears forces in the first global vertical flexural vibration mode.

Ingo Drummen

Senior Project Manager Hydrostructural Services

Create a MARIN account to stay updated

Report

Determining

loads for a challenging symmetrical ferry design

Particularly when it involves novel or complex ship structures, MARIN assists its clients with determining the loads on the ship that are necessary for its design.

Whipping factor derived

After obtaining the time series of the bending moments and shear forces, the so-called whipping factor was derived. The procedure for doing this is similar to the whipping factor derived for fatigue by Drummen et al. (2014). To obtain the corresponding factor for extreme bending moments and shear forces, the maximum value of the total bending moment or shear force signal was determined and divided by the maximum value obtained by applying a low-pass filter to the time series. The filter frequency was set to exclude the effect of global flexural vibrations.

Once the whipping factor was ascertained, a model based on wave steepness, wave steepness squared, speed and speed squared, was fitted. A number of alternatives were investigated. The present model gave the best results, however. The resulting model and coefficients were subsequently applied in the long-term analysis to obtain updated whipping results. It was found that whipping increased the vertical sagging and hogging bending moment by 70% and 60% respectively. Whipping increased the shear force by 80%.

In conclusion, combining numerical results with those from model tests made it possible to infer vertical bending moments and shear forces over the length of the ship from the measured accelerations. In addition, the design loads on the double-ended ferry were found in an efficient and accurate manner.

Waves were modelled with a JONSWAP spectrum. Relative wave directions with a 45° increment were considered alongside four forward speeds. For the analysis, the wave heights were split into low, medium and high and appropriate speeds for each of them were assumed. Heading and speed probabilities were considered equal.

Linear 3D potential flow method

Environmental and operational information was combined with calculated transfer functions of the vertical bending moments and shear forces. These were calculated with a linear 3D potential flow method. The fact that the method is linear implies that the contribution of whipping is not included. Results from model tests were used to make a correction on the linear results. To do this, the contribution of whipping had to be derived from the model tests.

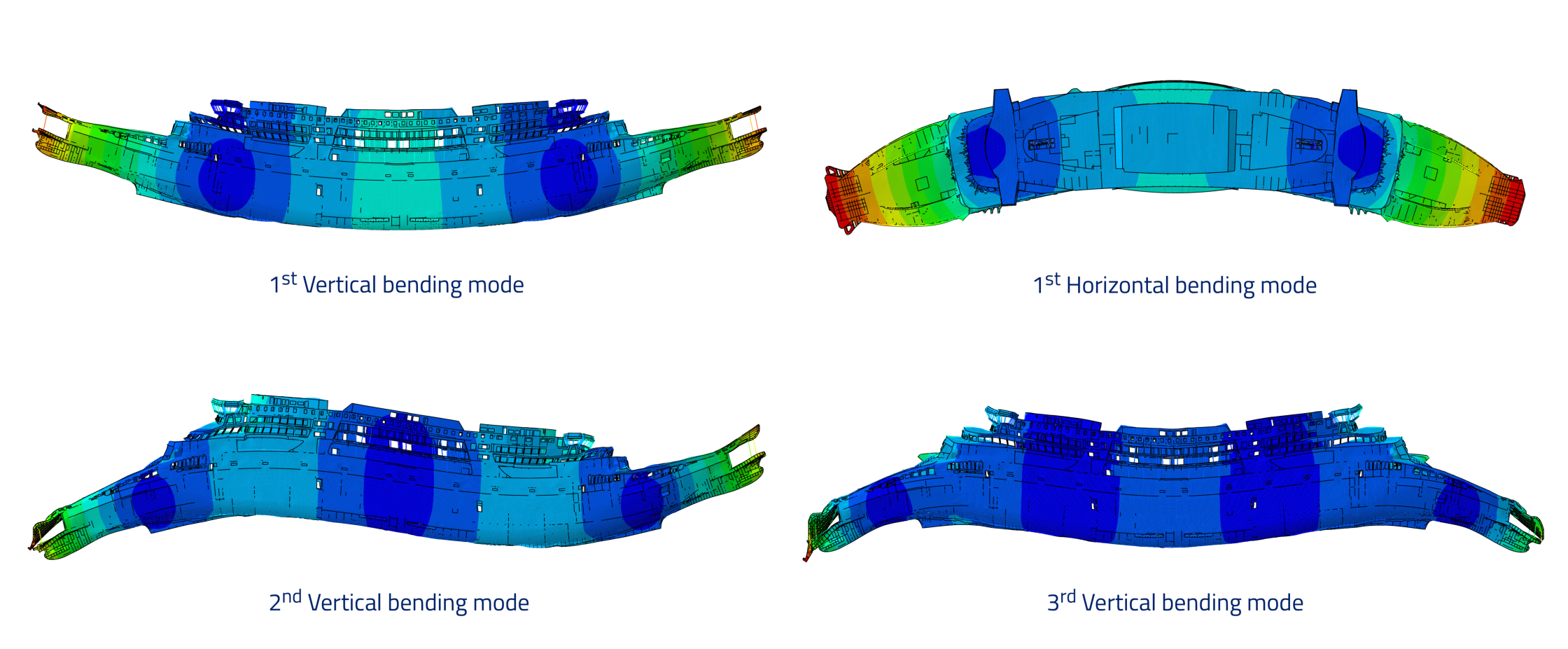

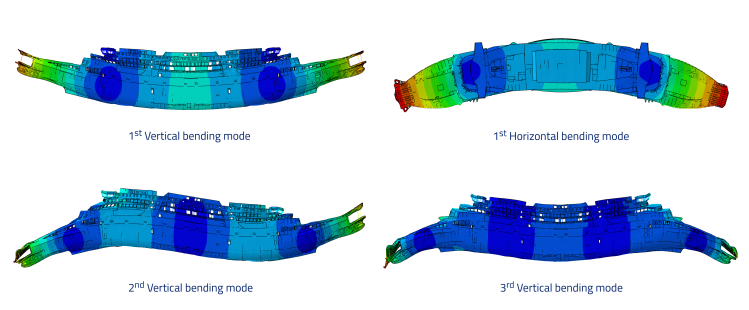

Accelerations in the model were measured at eight locations on the beam. The number of sensors is relevant because it impacts the number of modes that can be taken into account. Basically, the procedure assumes the accelerations are the sum of the accelerations in the selected vibration modes, where the amplitude of each mode is the variable to be determined. The approach we took is very similar to the one described by Schiere et al. (2017). The first three vertical and the first two horizontal global flexural vibration modes were used in the analysis. These are shown in Figure 2.

For this project, the loads were obtained from a combination of model tests (see previous article) and finite element simulations.

Maximum lifetime bending moments and shear forces are an important aspect of ship design. These global loads can be obtained from a long-term analysis. The first step involves the examination of the wave conditions, together with assumptions on how the ship will sail in these conditions. As the ferry sails in the English Channel between France and the UK, wave information from this region was used.

January 2026, no. 146

Figure 1: Illustration of bending moments and shears forces in the first global vertical flexural vibration mode.

Determining loads

for a challenging symmetrical ferry design

Figure 2: Illustration of bending moments and shears forces in the first global vertical flexural vibration mode.

Whipping factor derived

After obtaining the time series of the bending moments and shear forces, the so-called whipping factor was derived. The procedure for doing this is similar to the whipping factor derived for fatigue by Drummen et al. (2014). To obtain the corresponding factor for extreme bending moments and shear forces, the maximum value of the total bending moment or shear force signal was determined and divided by the maximum value obtained by applying a low-pass filter to the time series. The filter frequency was set to exclude the effect of global flexural vibrations.

Once the whipping factor was ascertained, a model based on wave steepness, wave steepness squared, speed and speed squared, was fitted. A number of alternatives were investigated. The present model gave the best results, however. The resulting model and coefficients were subsequently applied in the long-term analysis to obtain updated whipping results. It was found that whipping increased the vertical sagging and hogging bending moment by 70% and 60% respectively. Whipping increased the shear force by 80%.

In conclusion, combining numerical results with those from model tests made it possible to infer vertical bending moments and shear forces over the length of the ship from the measured accelerations. In addition, the design loads on the double-ended ferry were found in an efficient and accurate manner.

Ingo Drummen

Senior Project Manager Hydrostructural Services

Waves were modelled with a JONSWAP spectrum. Relative wave directions with a 45° increment were considered alongside four forward speeds. For the analysis, the wave heights were split into low, medium and high and appropriate speeds for each of them were assumed. Heading and speed probabilities were considered equal.

Linear 3D potential flow method

Environmental and operational information was combined with calculated transfer functions of the vertical bending moments and shear forces. These were calculated with a linear 3D potential flow method. The fact that the method is linear implies that the contribution of whipping is not included. Results from model tests were used to make a correction on the linear results. To do this, the contribution of whipping had to be derived from the model tests.

Accelerations in the model were measured at eight locations on the beam. The number of sensors is relevant because it impacts the number of modes that can be taken into account. Basically, the procedure assumes the accelerations are the sum of the accelerations in the selected vibration modes, where the amplitude of each mode is the variable to be determined. The approach we took is very similar to the one described by Schiere et al. (2017). The first three vertical and the first two horizontal global flexural vibration modes were used in the analysis. These are shown in Figure 2.

For this project, the loads were obtained from a combination of model tests (see previous article) and finite element simulations.

Maximum lifetime bending moments and shear forces are an important aspect of ship design. These global loads can be obtained from a long-term analysis. The first step involves the examination of the wave conditions, together with assumptions on how the ship will sail in these conditions. As the ferry sails in the English Channel between France and the UK, wave information from this region was used.

Interested? Contact us to discuss your options

Particularly when it involves novel or complex ship structures, MARIN assists its clients with determining the loads on the ship that are necessary for its design.

Create a MARIN account to stay updated

Report