Slide to compare front and rear.

External Hydrodynamic Loads on the Shaft of Azimuthing Thrusters and Podded Propulsors, Dang, J., Brouwer, J., 14th SNAME Propellers and Shafting Symposium, Sep 15, 2015

Stable sheet cavitation during full power crabbing (left) and nearly cavitation free design for the aft pods (right)

More info

January 2026, no. 146

Create a MARIN account to stay updated

Report

Pod propulsion within wide seakeeping operational profiles

Operating the world's largest double-ended ferry on an open sea route presents formidable challenges from both seakeeping and powering perspectives.

ABB's propeller design for the Azipods® proved instrumental in achieving this balance. The blades, identical for fore and aft propellers, were meticulously engineered to exhibit balanced cavitation performance, considering the 30% power share when used as the fore pods to prevent face cavitation and the 70% power share when used as the aft pods to limit back cavitation and cavitation-induced hull excitation levels.

MARIN employed its dedicated cavitation observation system, equipped with high-speed video cameras and over 20 pressure sensors positioned on the hull near each propeller, to accurately capture and evaluate the dynamics of cavitation. This comprehensive testing approach enabled precise determination of integrated vertical hull excitation forces caused by cavitation, both for the fore and aft pods, during different sailing conditions and even during crabbing manoeuvres with zero forward speed but significant azimuth angles. The final propeller design was extensively tested and judged to exhibit exceptional cavitation performance, while maintaining acceptable levels of hull excitation forces for all operational conditions.

Maximising passenger comfort

While optimising the propulsion system for efficiency, we also paid close attention to passenger comfort, ensuring that the ferry complied with the required class notations. To achieve this, it was essential to design propellers with excellent cavitation performance, limiting excitation forces on the hull and maintaining controlled vibration levels.

Furthermore, the propulsion systems were fine-tuned by adjusting the power share/split between the fore and aft pods. Extensive exploration of power distribution scenarios was performed, ultimately leading to the selection of a practical and optimal 30%-70% power share/split, ensuring that each pod operated within its capacity limits.

Thanks to our in-depth understanding of pod hydrodynamics and the development of dedicated pod model testing equipment, we have successfully assessed and tested designs for different types of ships equipped with pods, ranging from cruise ships, ferries, and yachts to supply vessels and offshore structures with dynamic positioning and tracking abilities.

To ensure the overall powering performance of the double-ended ferry, we conducted model tests in both deep and shallow water, evaluating a comprehensive matrix of vertical tilt angles and neutral steering setting angles for all pods, while maintaining a specified leg-out angle. This meticulous optimisation process aimed to avoid unfavourable interactions such as Coanda effects (the tendency of a fluid jet to adhere to and follow a curved surface too long) and flow misalignment.

Following the initial powering and seakeeping tests, OSK further refined the hull form under the guidance of MARIN, resulting in a final design suitable for deep and shallow water operations, specific to this unique double-ended ferry operating on an open sea route.

Pod expertise

MARIN's expertise in pod hydrodynamics, gained through decades of collaboration with pod manufacturers, shipyards, and design offices, played a pivotal role in optimising the performance of the azimuth podded propulsors. Studies encompassed various aspects, including propulsive efficiency, interaction effects, bollard and dynamic positioning capabilities, cavitation, comfort, crabbing, dynamic loads, and safe-return-to-port (SRTP) functionality for pod-equipped vessels.

Seakeeping considerations are paramount to protect the equipment from slamming damage, while powering requirements demand minimising fuel consumption and emissions. It is essential to navigate the intricate dynamics of pod-pod and pod-hull interactions, avoiding any detrimental effects, irrespective of water depth—be it deep or shallow.

Right from the initial design stage, MARIN closely collaborated with GSI and OSK to identify an optimal hull form that would ensure low resistance and high propulsion efficiency, while also safeguarding the hull against slamming at the bow and stern. Extensive computational fluid dynamics (CFD) calculations and line optimisations were carried out.

Fore pods and ABB Azipod® DO1600.

Interested? Contact us to discuss your options

Jie Dang

Senior Project Manager, Powering

Jie Dang stresses that MARIN’s decades of expertise - encompassing numerical simulations, experiments, and industry experience – allowed them to make the most accurate assessment of the complex propulsion system for the double-ended ferry. Jie commented: “Our dedication to studying and comprehending the hydrodynamics of podded propulsors proved essential in achieving optimal outcomes for these pods, especially important given their wide range of operational profiles. The sea trial results unequivocally demonstrated the precision of the speed-power predictions derived from the model tests, confirming that the ship's powering performance, including speed-power characteristics and passenger comfort, aligned flawlessly with the initial predictions.”

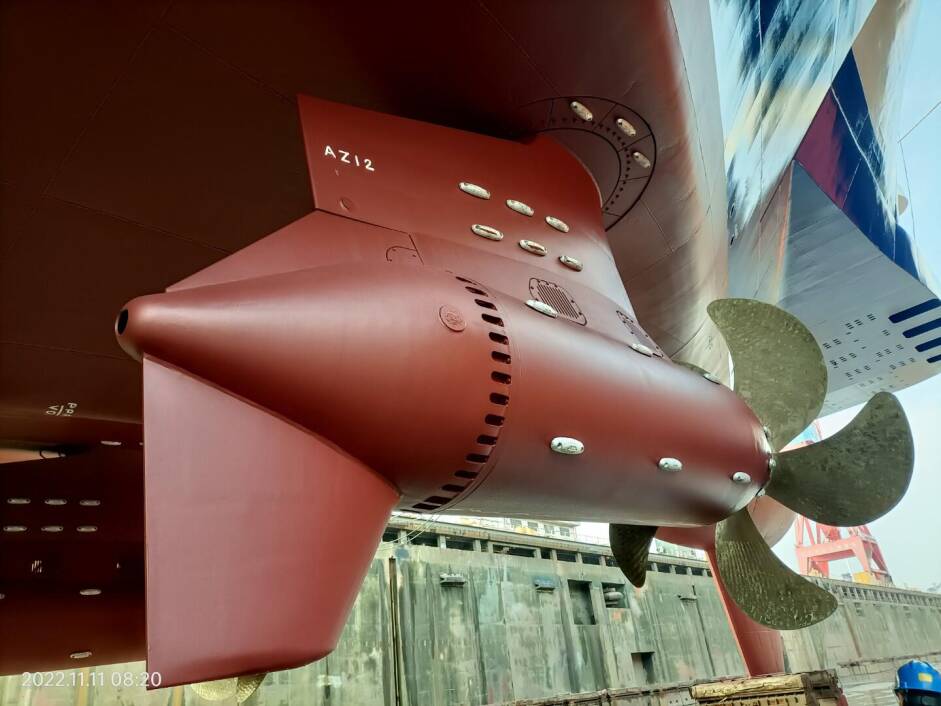

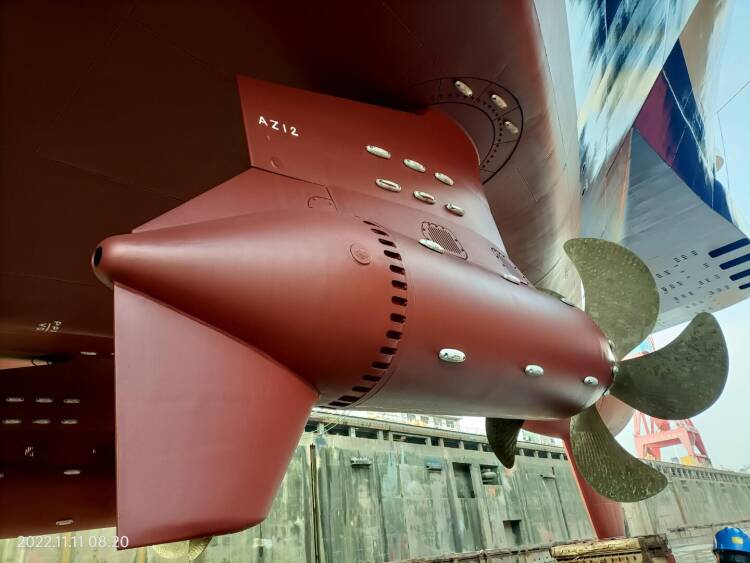

Fitting pods in drydock.

Stable sheet cavitation during full power crabbing (left) and nearly cavitation free design for the aft pods (right)

External Hydrodynamic Loads on the Shaft of Azimuthing Thrusters and Podded Propulsors, Dang, J., Brouwer, J., 14th SNAME Propellers and Shafting Symposium, Sep 15, 2015

More info

Jie Dang

Senior Project Manager, Powering

January 2026, no. 146

Maximising passenger comfort

While optimising the propulsion system for efficiency, we also paid close attention to passenger comfort, ensuring that the ferry complied with the required class notations. To achieve this, it was essential to design propellers with excellent cavitation performance, limiting excitation forces on the hull and maintaining controlled vibration levels.

Furthermore, the propulsion systems were fine-tuned by adjusting the power share/split between the fore and aft pods. Extensive exploration of power distribution scenarios was performed, ultimately leading to the selection of a practical and optimal 30%-70% power share/split, ensuring that each pod operated within its capacity limits.

Fore pods and ABB Azipod® DO1600.

Thanks to our in-depth understanding of pod hydrodynamics and the development of dedicated pod model testing equipment, we have successfully assessed and tested designs for different types of ships equipped with pods, ranging from cruise ships, ferries, and yachts to supply vessels and offshore structures with dynamic positioning and tracking abilities.

To ensure the overall powering performance of the double-ended ferry, we conducted model tests in both deep and shallow water, evaluating a comprehensive matrix of vertical tilt angles and neutral steering setting angles for all pods, while maintaining a specified leg-out angle. This meticulous optimisation process aimed to avoid unfavourable interactions such as Coanda effects (the tendency of a fluid jet to adhere to and follow a curved surface too long) and flow misalignment.

Fitting pods in drydock.

Jie Dang stresses that MARIN’s decades of expertise - encompassing numerical simulations, experiments, and industry experience – allowed them to make the most accurate assessment of the complex propulsion system for the double-ended ferry. Jie commented: “Our dedication to studying and comprehending the hydrodynamics of podded propulsors proved essential in achieving optimal outcomes for these pods, especially important given their wide range of operational profiles. The sea trial results unequivocally demonstrated the precision of the speed-power predictions derived from the model tests, confirming that the ship's powering performance, including speed-power characteristics and passenger comfort, aligned flawlessly with the initial predictions.”

Slide to compare front and rear.

Following the initial powering and seakeeping tests, OSK further refined the hull form under the guidance of MARIN, resulting in a final design suitable for deep and shallow water operations, specific to this unique double-ended ferry operating on an open sea route.

Pod expertise

MARIN's expertise in pod hydrodynamics, gained through decades of collaboration with pod manufacturers, shipyards, and design offices, played a pivotal role in optimising the performance of the azimuth podded propulsors. Studies encompassed various aspects, including propulsive efficiency, interaction effects, bollard and dynamic positioning capabilities, cavitation, comfort, crabbing, dynamic loads, and safe-return-to-port (SRTP) functionality for pod-equipped vessels.

Seakeeping considerations are paramount to protect the equipment from slamming damage, while powering requirements demand minimising fuel consumption and emissions. It is essential to navigate the intricate dynamics of pod-pod and pod-hull interactions, avoiding any detrimental effects, irrespective of water depth—be it deep or shallow.

Right from the initial design stage, MARIN closely collaborated with GSI and OSK to identify an optimal hull form that would ensure low resistance and high propulsion efficiency, while also safeguarding the hull against slamming at the bow and stern. Extensive computational fluid dynamics (CFD) calculations and line optimisations were carried out.

Operating the world's largest double-ended ferry on an open sea route presents formidable challenges from both seakeeping and powering perspectives.

Pod propulsion within wide seakeeping operational profiles

Interested? Contact us to discuss your options

Create a MARIN account to stay updated

Report