“Operating such a large and complex ferry requires careful studies to define procedures in ports and to ensure sufficient operability.”

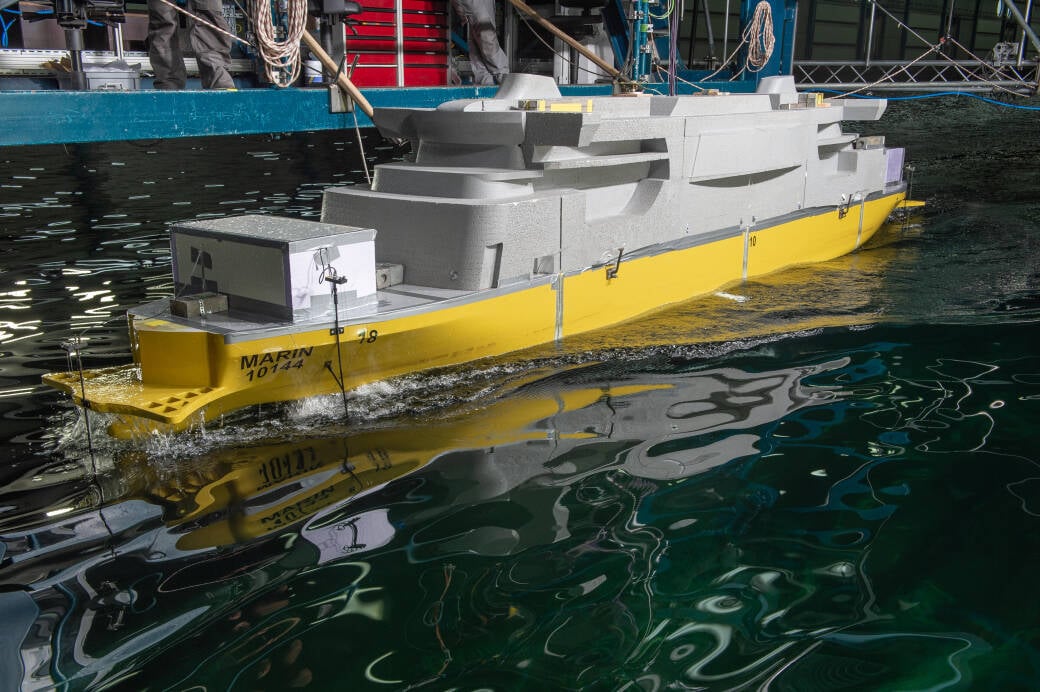

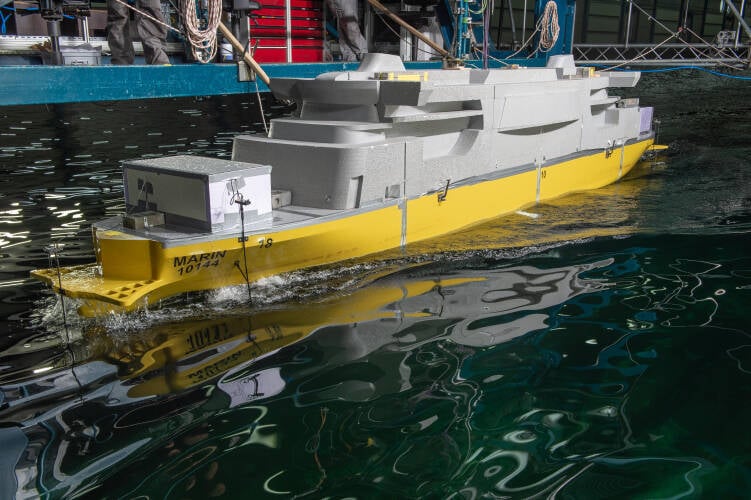

Model tests in waves.

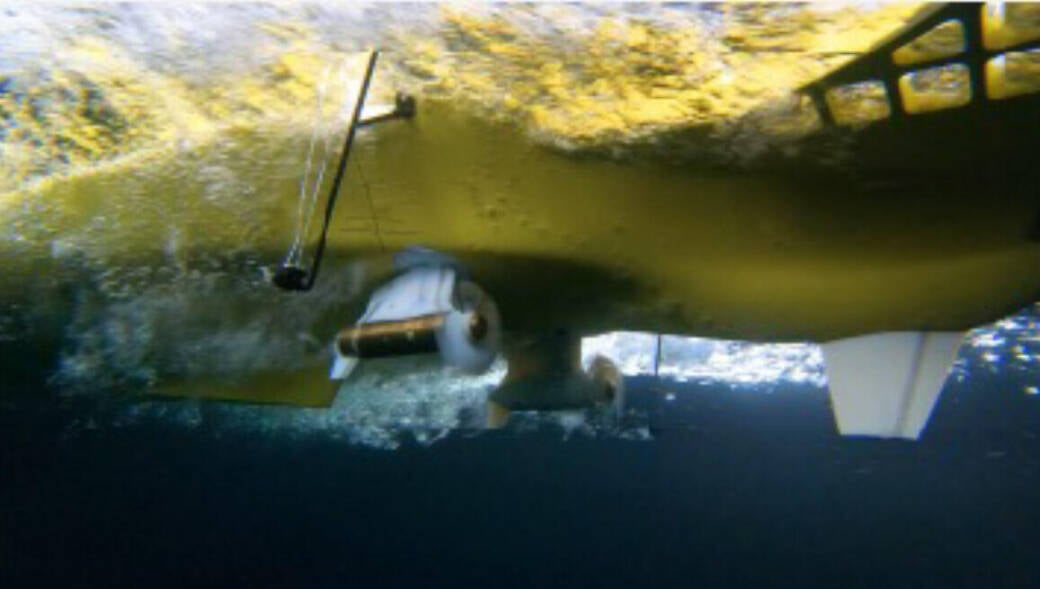

Two 360° rotatable azimuthing pods at each end of the vessel.

Photo GSI

Ferry under construction at GSI.

Chen Hao, Chief Design Officer of GSI

Chief Design Officer of Guangzhou Shipyard International (GSI), Chen Hao, says he is extremely proud to have worked on such a ground-breaking ferry project. “This was an important moment for GSI. P&O Ferries was one of the first companies to start a maritime trade with China in the 19thcentury, and this is also the first time in its history that it has awarded a shipbuilding contract to a Chinese company.”

But there were indeed challenges

when building this one-of-a-kind vessel, he stresses, such as optimising the hull lines to balance the various functions, including manoeuvring,

seakeeping, fuel oil consumption, vibrations, stability and so on.

Mr Chen says GSI, which is already a frontrunner in the passenger ship market, has quite some ambitions for the sector. “When you consider the average age of RoPax vessels worldwide, they are typically much older than cargo vessels, therefore we expect newbuilding demand to be robust over the next 10 years.”

Collaborating with MARIN on this project has been very rewarding, he emphasises. “MARIN is the best hydrodynamic institute on the planet and always offers excellent service to GSI. The institute has undoubtedly helped GSI improve the design and mitigate any potential risks. Their highly skilled professionals are proactive and were able to provide useful input, even before the model test campaigns, and this has helped GSI find the best solution. We wish MARIN every success in creating a brilliant future and personally, I hope to see the MARIN colleagues again very soon.”

Combining MARIN’s broad expertise

The unique characteristics of this double-ender demanded several in-depth studies to investigate, evaluate and test the different design options. This was the perfect opportunity for MARIN to bring together its broad hydrodynamic, structural and nautical expertise. Through a thorough investigation combining numerical and experimental methods, MARIN supported GSI and the other project members with an extensive study covering a diverse range of topics.

Apart from the optimisation of the hull form to minimise the water resistance - ensuring lower energy consumption and higher comfort (contribution on propulsion), two aspects are remarkable:

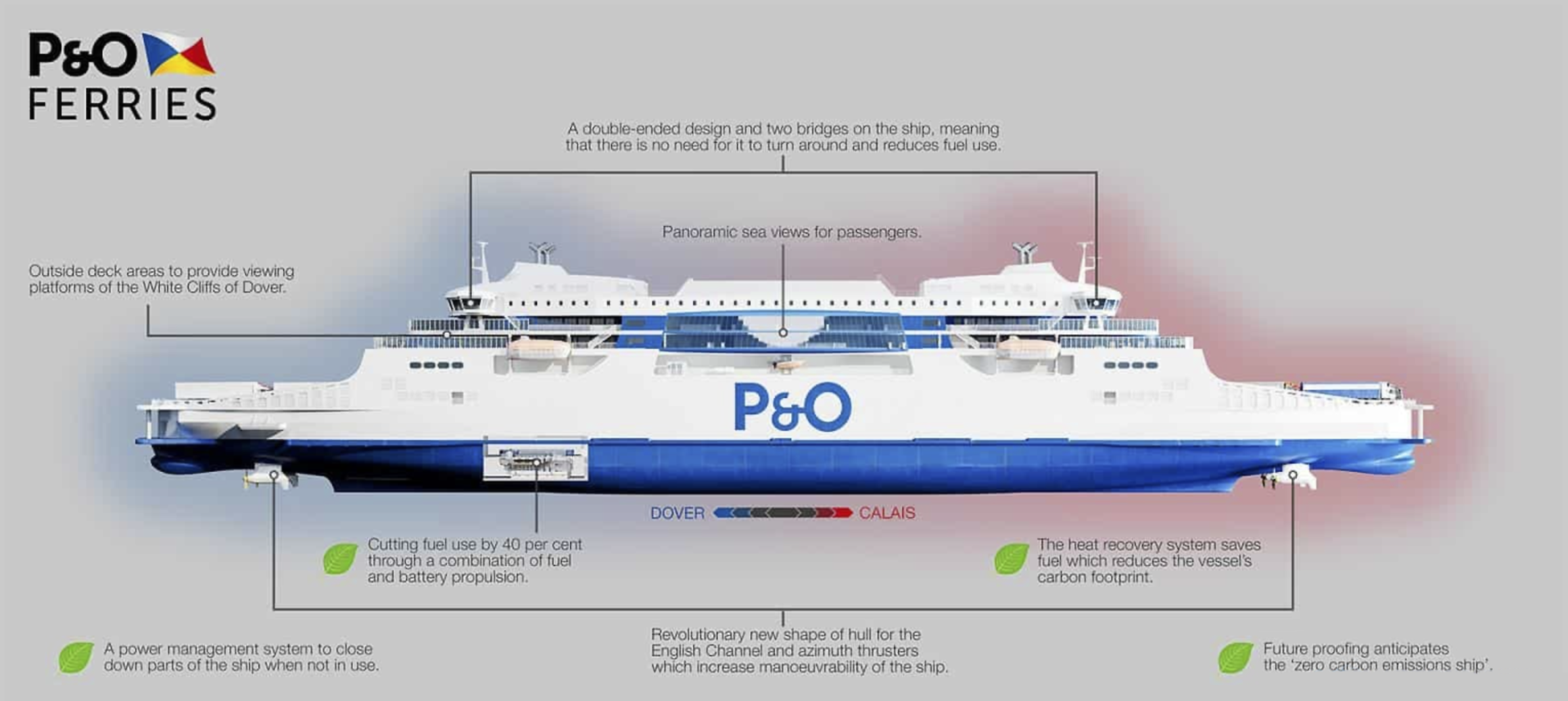

Aiming to be a future-proof design, the engine room is prepared to undergo a “zero-emission conversion” which will enable additional batteries to be fitted instead of diesel engines when adequate supply facilities become available in the ports of Calais and Dover. Finally, the ferry features heat-recovery systems and a power-management system that closes down parts of the ship when not in use.

To ensure top performance in both directions, the hull is symmetrical with respect to the midship station. As a consequence, the ferry has two bulbous ends, optimised for service in both directions. The vessel is also equipped with two sets of retractable stabiliser fins (one for each sailing direction), to improve passenger comfort during the journey. Among the few non-symmetrical elements are the platforms used to berth. As each ship end will always berth in the same port, the platforms are optimised for the terminals.

Create a MARIN account to stay updated

Report

January 2026, no. 146

Interested? Contact us to discuss your options

Throughout this edition of Report magazine you will find comprehensive articles about each part of the design and testing process. We highlight the intensive cooperation within the different departments of MARIN and how our hydrodynamic, structural and nautical experts work behind the scenes to ensure the success of these complex projects.

Ensuring safe operations in harbours: Operating such a large and complex ferry requires careful studies to define procedures in ports and to ensure sufficient operability. A wide range of manoeuvring experiments were carried out to derive a high-fidelity simulation model. See the article on the manoeuvring model preparation. This model was implemented into a real-time bridge simulator. A number of scenarios were defined with the ferry entering the ports and berthing, aiming to determine the maximum environmental conditions under which manoeuvres could be safely executed. See the final article on the full-scale port manoeuvring simulations.

A double-ended ferry in open seas: sailing with a double-ended ferry of this size in the English Channel means facing open-sea environmental conditions, while the hull shape is strongly limited by its bow/stern symmetry. Seakeeping (motions in waves) and structural aspects were investigated through a large range of model tests by measuring hull loads and bending moments, as well as ship motions in operation. See both detailed articles on seakeeping (motions & loads) and structural response.

MARIN performs landmark industry project on the largest double-ended ferry in the world

“The unique characteristics of this double-ender demanded several in-depth studies to investigate, evaluate and test the different design options.”

Better Ships, Blue Oceans

With a length of 230 m and a capacity of 1,500 passengers, the ferry travels along a 22-mile route in open sea, connecting Calais in France to Dover in the United Kingdom. It’s also by far the biggest ferry on the Dover-Calais route.

Sails in either direction

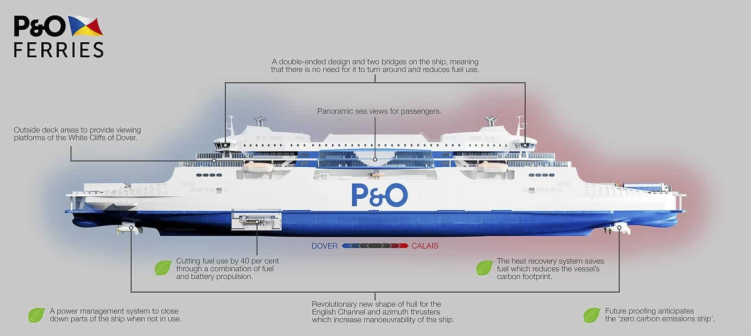

Designed by Danish company OSK Design, the double-ended ferry is almost fully symmetrical and can sail in either direction. Instead of turning the ship around to leave the port, the ferry will simply depart in the opposite direction, saving a considerable amount of harbour time on each of the 90-minute journeys.

The ship features two 7.5 MW azimuthing pods at each end of the vessel. These 360° rotatable Azipods are manufactured by ABB. When the ferry reverses its sailing direction, the pulling Azipods are rotated 180° and the crew moves to the opposite main deck. Power is provided by a hybrid propulsion solution, including 8.8 MWh batteries and diesel generators and the main engines are supplied by Wärtsilä.

MARIN has combined its broad hydrodynamic, structural and nautical expertise to support the development of the concept design and to ensure safe operations within the ports and at sea.

Upon entering service, the P&O Pioneer was directly awarded the Shippax Ferry Concept & Efficiency Award for its design as the world's largest double-ender hybrid shuttle ferry, which uses an electric-diesel propulsion system to substantially reduce fuel consumption and emissions.

This unique vessel, operated by the British shipping company P&O Ferries and denoted as the Pioneer class, was the result of a new cooperation between MARIN, the ship designer OSK Design and the shipbuilder Guangzhou Shipyard International (GSI) of China. The Pioneer and its sister ship Liberté were delivered in June 2023 and March 2024 respectively.

In an important maritime industry milestone, the largest double-ended ferry ever seen in the world is now sailing across the English Channel.

Artist impression. Photo P&O Ferries.

Ferry under construction at GSI.

Photo GSI

Chen Hao, Chief Design Officer of GSI

Chief Design Officer of Guangzhou Shipyard International (GSI), Chen Hao, says he is extremely proud to have worked on such a ground-breaking ferry project. “This was an important moment for GSI. P&O Ferries was one of the first companies to start a maritime trade with China in the 19thcentury, and this is also the first time in its history that it has awarded a shipbuilding contract to a Chinese company.”

But there were indeed challenges

when building this one-of-a-kind vessel, he stresses, such as optimising the hull lines to balance the various functions, including manoeuvring,

seakeeping, fuel oil consumption, vibrations, stability and so on.

Mr Chen says GSI, which is already a frontrunner in the passenger ship market, has quite some ambitions for the sector. “When you consider the average age of RoPax vessels worldwide, they are typically much older than cargo vessels, therefore we expect newbuilding demand to be robust over the next 10 years.”

Collaborating with MARIN on this project has been very rewarding, he emphasises. “MARIN is the best hydrodynamic institute on the planet and always offers excellent service to GSI. The institute has undoubtedly helped GSI improve the design and mitigate any potential risks. Their highly skilled professionals are proactive and were able to provide useful input, even before the model test campaigns, and this has helped GSI find the best solution. We wish MARIN every success in creating a brilliant future and personally, I hope to see the MARIN colleagues again very soon.”

Throughout this edition of Report magazine you will find comprehensive articles about each part of the design and testing process. We highlight the intensive cooperation within the different departments of MARIN and how our hydrodynamic, structural and nautical experts work behind the scenes to ensure the success of these complex projects.

Two 360° rotatable azimuthing pods at each end of the vessel.

Ensuring safe operations in harbours: Operating such a large and complex ferry requires careful studies to define procedures in ports and to ensure sufficient operability. A wide range of manoeuvring experiments were carried out to derive a high-fidelity simulation model. See the article on the manoeuvring model preparation. This model was implemented into a real-time bridge simulator. A number of scenarios were defined with the ferry entering the ports and berthing, aiming to determine the maximum environmental conditions under which manoeuvres could be safely executed. See the final article on the full-scale port manoeuvring simulations.

Ferry under construction at GSI.

Model tests in waves.

A double-ended ferry in open seas: sailing with a double-ended ferry of this size in the English Channel means facing open-sea environmental conditions, while the hull shape is strongly limited by its bow/stern symmetry. Seakeeping (motions in waves) and structural aspects were investigated through a large range of model tests by measuring hull loads and bending moments, as well as ship motions in operation. See both detailed articles on seakeeping (motions & loads) and structural response.

Combining MARIN’s broad expertise

The unique characteristics of this double-ender demanded several in-depth studies to investigate, evaluate and test the different design options. This was the perfect opportunity for MARIN to bring together its broad hydrodynamic, structural and nautical expertise. Through a thorough investigation combining numerical and experimental methods, MARIN supported GSI and the other project members with an extensive study covering a diverse range of topics.

Apart from the optimisation of the hull form to minimise the water resistance - ensuring lower energy consumption and higher comfort (contribution on propulsion), two aspects are remarkable:

Interested? Contact us to discuss your options

“Operating such a large and complex ferry requires careful studies to define procedures in ports and to ensure sufficient operability.”

Aiming to be a future-proof design, the engine room is prepared to undergo a “zero-emission conversion” which will enable additional batteries to be fitted instead of diesel engines when adequate supply facilities become available in the ports of Calais and Dover. Finally, the ferry features heat-recovery systems and a power-management system that closes down parts of the ship when not in use.

To ensure top performance in both directions, the hull is symmetrical with respect to the midship station. As a consequence, the ferry has two bulbous ends, optimised for service in both directions. The vessel is also equipped with two sets of retractable stabiliser fins (one for each sailing direction), to improve passenger comfort during the journey. Among the few non-symmetrical elements are the platforms used to berth. As each ship end will always berth in the same port, the platforms are optimised for the terminals.

“The unique characteristics of this double-ender demanded several in-depth studies to investigate, evaluate and test the different design options.”

Report

The ship features two 7.5 MW azimuthing pods at each end of the vessel. These 360° rotatable Azipods are manufactured by ABB. When the ferry reverses its sailing direction, the pulling Azipods are rotated 180° and the crew moves to the opposite main deck. Power is provided by a hybrid propulsion solution, including 8.8 MWh batteries and diesel generators and the main engines are supplied by Wärtsilä.

Artist impression. Photo P&O Ferries.

January 2026, no. 146

MARIN has combined its broad hydrodynamic, structural and nautical expertise to support the development of the concept design and to ensure safe operations within the ports and at sea.

Upon entering service, the P&O Pioneer was directly awarded the Shippax Ferry Concept & Efficiency Award for its design as the world's largest double-ender hybrid shuttle ferry, which uses an electric-diesel propulsion system to substantially reduce fuel consumption and emissions.

The µMMS is not only applicable for FOWT, but also for other small floaters and ships. The new measurement system makes it possible to accurately test small vessels, without the unwanted effect of the measurement cables.

For example, this year the Dutch Ministry of Infrastructure and Water Management contracted MARIN to investigate the dynamics that are involved in the capsizing of beam trawlers. The main goal of this project was to investigate the capsize risk in relation to fishing operations and the stability criteria.

Initially, we had planned to make a free sailing model for the tests that connects to the measurement system on the carriage. The combination of a small vessel and the high wave height in the tests resulted in a model weight of less than 100 kg. Given the small model size, low forces can have an impact on the rolling behaviour of the vessel. Therefore, to minimise the impact that the cables can have on the motions of the vessel, we minimised the number of sensors on board to the bare minimum. Additionally, we planned to use thinner cables than normal to reduce the weight even further.

The µMMS became available when we were designing the model. This offered the opportunity to make the model completely wireless and to measure more signals within the budget of the project. Without the measurement wires between the carriage and the model, the test setup was more versatile. No precautions were necessary to avoid interference from the measurement cables.

With a length of 230 m and a capacity of 1,500 passengers, the ferry travels along a 22-mile route in open sea, connecting Calais in France to Dover in the United Kingdom. It’s also by far the biggest ferry on the Dover-Calais route.

Sails in either direction

Designed by Danish company OSK Design, the double-ended ferry is almost fully symmetrical and can sail in either direction. Instead of turning the ship around to leave the port, the ferry will simply depart in the opposite direction, saving a considerable amount of harbour time on each of the 90-minute journeys.

The ship features two 7.5 MW azimuthing pods at each end of the vessel. These 360° rotatable Azipods are manufactured by ABB. When the ferry reverses its sailing direction, the pulling Azipods are rotated 180° and the crew moves to the opposite main deck. Power is provided by a hybrid propulsion solution, including 8.8 MWh batteries and diesel generators and the main engines are supplied by Wärtsilä.

This unique vessel, operated by the British shipping company P&O Ferries and denoted as the Pioneer class, was the result of a new cooperation between MARIN, the ship designer OSK Design and the shipbuilder Guangzhou Shipyard International (GSI) of China. The Pioneer and its sister ship Liberté were delivered in June 2023 and March 2024 respectively.

In an important maritime industry milestone, the largest double-ended ferry ever seen in the world is now sailing across the English Channel.

MARIN performs landmark industry project on the largest double-ended ferry in the world

Create a MARIN account to stay updated