Create a MARIN account to stay updated

April 2023, no. 135

Report

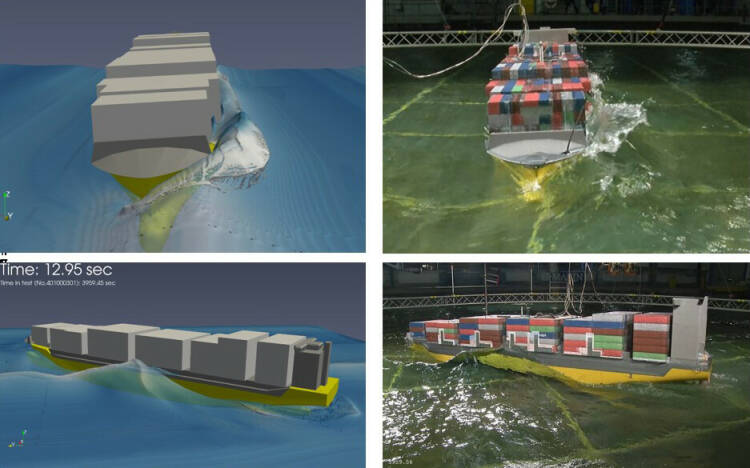

High speed green water impact in 4.5-metre-high beam waves.

With the accident of the Ultra Large Container Ship “MSC Zoë” in January 2019, during which 342 containers were lost overboard a few miles off the Dutch Wadden Islands, the problem of recurring container losses and the associated pollution in an area labelled as “Particularly Sensitive Sea Area” regained public attention.

While the initial focus was on the larger vessels, more recent container losses from the 169 m “OOCL Rauma” and the 170 m “Baltic Tern” - representing five containers in both cases - showed that feeder ships are also at risk. With a relatively low freeboard, feeder ships are more vulnerable to green water than larger vessels. Therefore, the Dutch Ministry of Infrastructure and Water Management asked MARIN to conduct a study on the risk of green water exposure for feeder ships, in view of refining the recommendations sent by the Netherlands Coastguard to ships in the area.

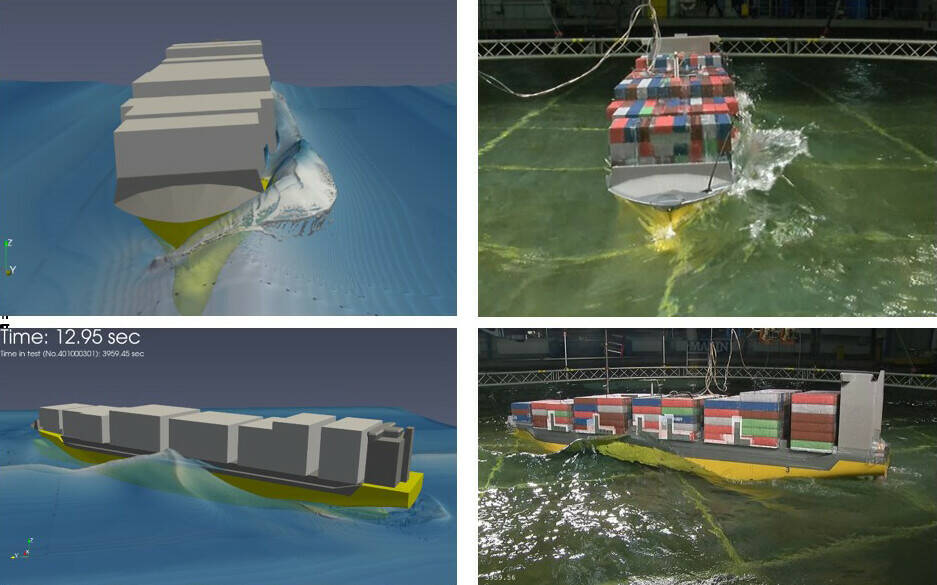

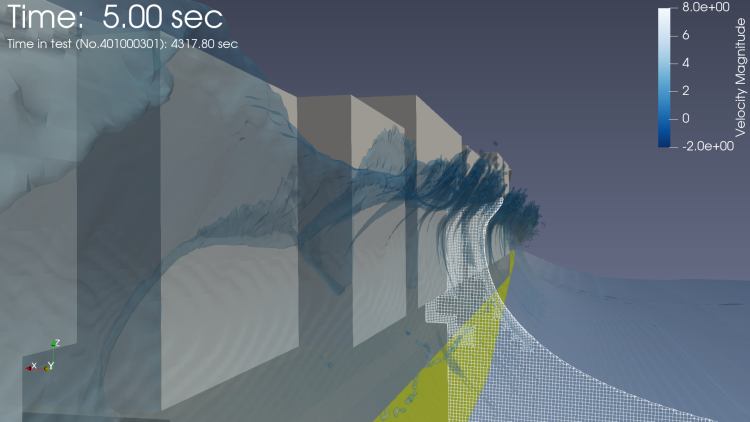

Snapshots of green water event in 4.5 m high beam waves (top) and 4.5 m high stern-quartering waves (bottom).

Combined approach deploying model tests, CFD and FEM analysis

Green water belongs to the most complex hydrodynamic problems. Therefore, getting a grasp on the loads induced and understanding how containers stacked on deck will react required a specific approach, consisting of model tests in a wave basin and computations. In the first place, model tests were conducted to quantify the influence of freeboard height and the container arrangement on deck, wave characteristics and bathymetry on the frequency and amplitude of green water loads. To quantify the loads, the model was instrumented with several force panels spread over the side of the lowest containers on deck.

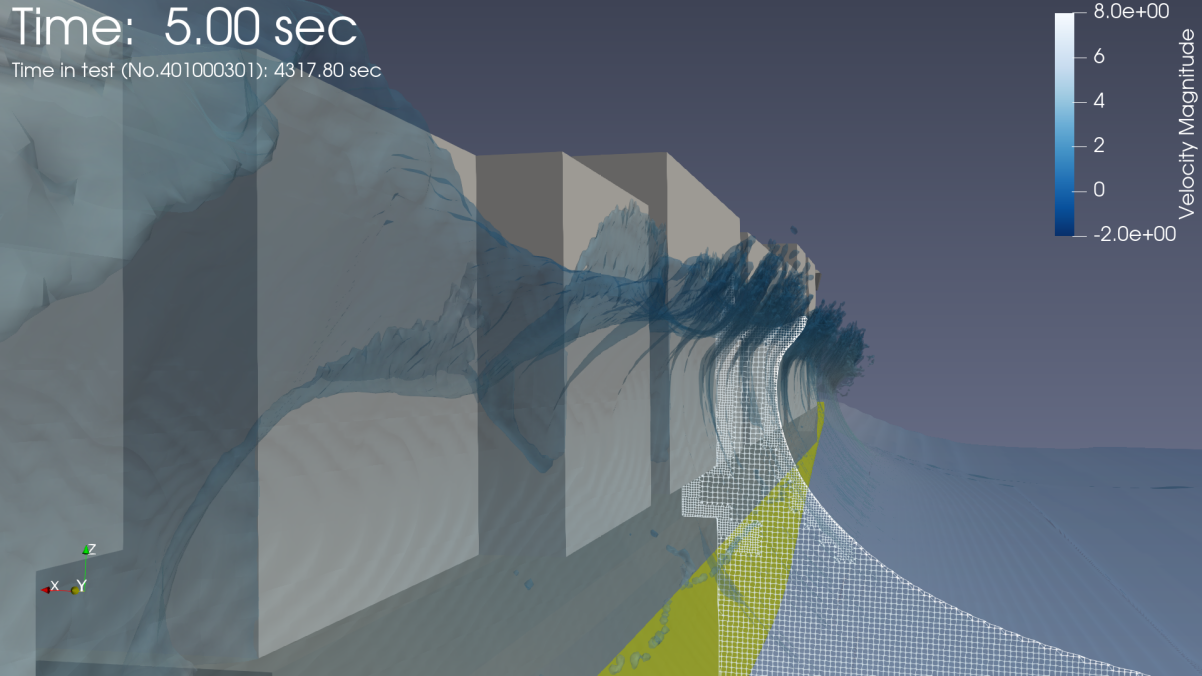

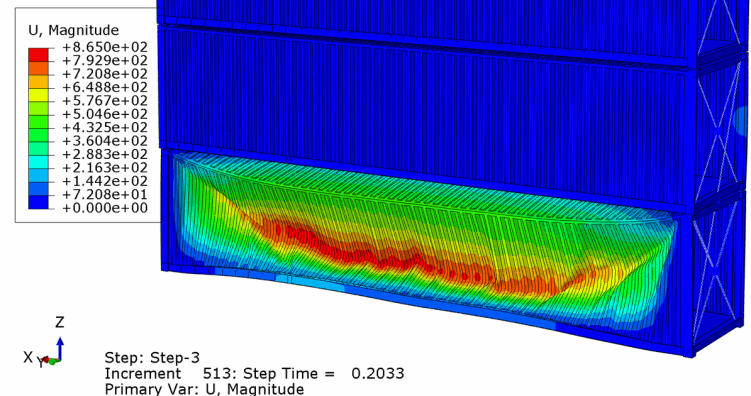

A selection of the measured green water events throughout the campaign was further scrutinised using CFD and FEM analyses. MARIN’s CFD code COMFLOW is used to replicate the events numerically so that the wave-induced pressure distribution on the containers is obtained. The pressure distribution is then input into the FE model of a container stack (see Figure) to determine the deformation in time introduced by the load. By comparing the measured deformations and stresses in the different elements of the stacks with applicable criteria, MARIN could see whether there is going to be only limited damage or if a complete stack loss is likely.

Changing course mitigates risks

Model tests showed that the largest wave loads occur in high, steep waves from the beam that break against the ship’s side shell and side containers. While the wave height at which green water loads on containers are observed depends on the amount of freeboard, loads are already observed on the lowest containers on the deck during the tests with a significant wave height of 1.8 m. The frequency and amplitude of the wave loads are also significantly influenced by the wave heading relative to the ship, as sailing in quartering waves (from 30 degrees off beam waves) yields much less green water than in beam waves. This suggests that a change in course can effectively mitigate the risk of experiencing large green water loads. Water depth was also found to have an important effect on green water loads, with the most frequent and largest loads being measured in the shallowest condition. However, its influence is only observed for wave heights above a given threshold. Differences were also noted between the two container arrangements on deck, however only in the loads originating from waves climbing on the hull after a slam had occurred.

Dynamic loads lead to container losses

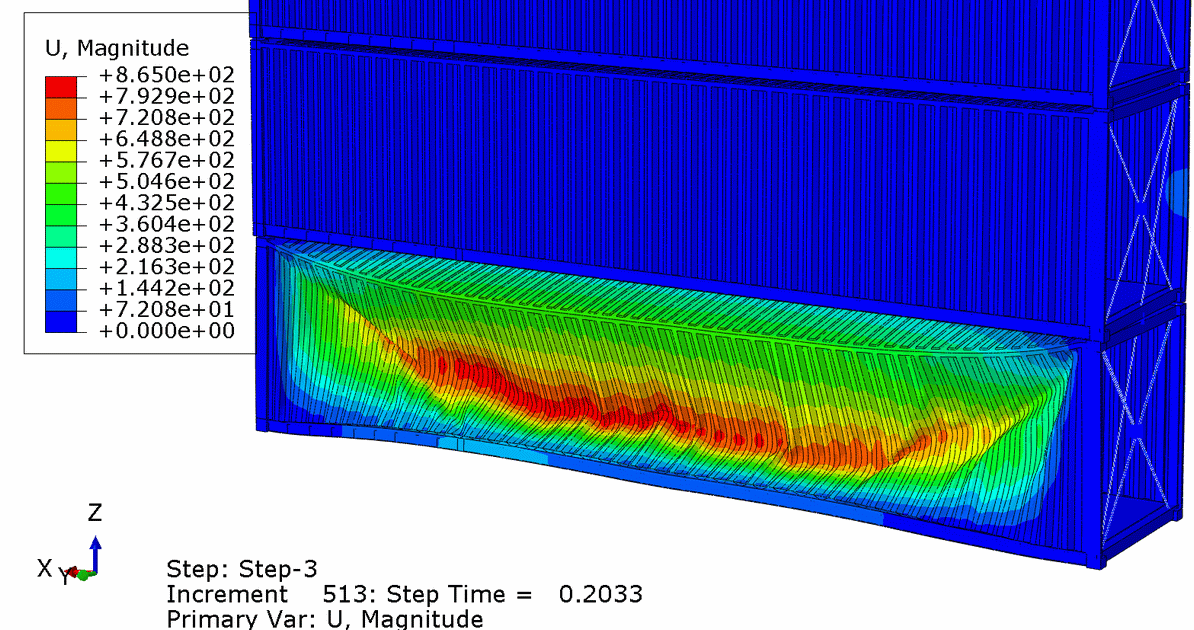

The FE model of the container stack showed various results depending on the wave loads applied. While the milder loads did not result in any damage to the stack, the higher loads observed in wave conditions that happen a few times per year in the area, resulted in more significant damage. In calculations where more ‘hydrostatic’ types of loads were noted, damage occurred at the bottom container side panel and bottom floor, with deformations on the side panel sometimes exceeding 50 cm. But this did not result in stack losses. However, in calculations where more ‘dynamic’ loads were observed - characterised by higher load peak amplitudes and water particle

velocities - the bending on the side panel and longitudinal beams is such that it results in twist-lock failure. In that case, a total loss of the container stack is bound to occur.

Revised recommendations

Ultimately, the findings of the study led the Ministry and the Dutch Coastguard to revise their route and safety recommendations for containerships sailing near the west Frisian Islands. Ships of between 100 and 200 m are now advised to alter their course and take appropriate measures to avoid losing containers when the significant wave height exceeds 3 m.

Container deformation after impact in 4.5-metre-high beam waves.

During his 38-year sailing career, Captain Krijt has served on all kinds of oceangoing vessels, which culminated in being a Master on the largest Dutch container vessel of the early 21 century.

After his retirement in 2004, he became a simulator operator/instructor at MARIN and has been involved in many research projects and studies since then.

In the case of head seas = waves head on

Most feeders nowadays have raised forecastles and water breakers installed. Some of them even have the forecastle completely covered ending in a water breaker just in front of the stacked containers. This will definitely contribute to safety and avoid containers being hit by green water over the bow.

Older and smaller feeders have raised forecastles, but not as prominent and the water breaker (if fitted) is not as effective. It should be taken into account that the bow flair of these vessels, due to a smaller beam, is not as prominent. Therefore, shipping green water during head on seas will be more likely.

In the case of beam seas = waves against the side shell

Due to a low freeboard, the containers in the side of a feeder are more vulnerable to green water and consequently can easily be damaged. Research learned that this already happens in relatively low beam waves. Damaged containers lose their structural strength and container stacks will collapse and/or fall overboard.

However, from the navigation bridge, the situation can be relatively well monitored on the smaller vessels.

More info:

Extreme behaviour in shallow water explains why large containerships can lose containers above the Dutch Wadden islands

April 2023, no. 135

Extreme behaviour in shallow water explains why large containerships can lose containers above the Dutch Wadden islands

More info:

In the case of beam seas = waves against the side shell

Due to a low freeboard, the containers in the side of a feeder are more vulnerable to green water and consequently can easily be damaged. Research learned that this already happens in relatively low beam waves. Damaged containers lose their structural strength and container stacks will collapse and/or fall overboard.

However, from the navigation bridge, the situation can be relatively well monitored on the smaller vessels.

In the case of head seas = waves head on

Most feeders nowadays have raised forecastles and water breakers installed. Some of them even have the forecastle completely covered ending in a water breaker just in front of the stacked containers. This will definitely contribute to safety and avoid containers being hit by green water over the bow.

Older and smaller feeders have raised forecastles, but not as prominent and the water breaker (if fitted) is not as effective. It should be taken into account that the bow flair of these vessels, due to a smaller beam, is not as prominent. Therefore, shipping green water during head on seas will be more likely.

During his 38-year sailing career, Captain Krijt has served on all kinds of oceangoing vessels, which culminated in being a Master on the largest Dutch container vessel of the early 21 century.

After his retirement in 2004, he became a simulator operator/instructor at MARIN and has been involved in many research projects and studies since then.

Container deformation after impact in 4.5-metre-high beam waves.

velocities - the bending on the side panel and longitudinal beams is such that it results in twist-lock failure. In that case, a total loss of the container stack is bound to occur.

Revised recommendations

Ultimately, the findings of the study led the Ministry and the Dutch Coastguard to revise their route and safety recommendations for containerships sailing near the west Frisian Islands. Ships of between 100 and 200 m are now advised to alter their course and take appropriate measures to avoid losing containers when the significant wave height exceeds 3 m.

Dynamic loads lead to container losses

The FE model of the container stack showed various results depending on the wave loads applied. While the milder loads did not result in any damage to the stack, the higher loads observed in wave conditions that happen a few times per year in the area, resulted in more significant damage. In calculations where more ‘hydrostatic’ types of loads were noted, damage occurred at the bottom container side panel and bottom floor, with deformations on the side panel sometimes exceeding 50 cm. But this did not result in stack losses. However, in calculations where more ‘dynamic’ loads were observed - characterised by higher load peak amplitudes and water particle

Changing course mitigates risks

Model tests showed that the largest wave loads occur in high, steep waves from the beam that break against the ship’s side shell and side containers. While the wave height at which green water loads on containers are observed depends on the amount of freeboard, loads are already observed on the lowest containers on the deck during the tests with a significant wave height of 1.8 m. The frequency and amplitude of the wave loads are also significantly influenced by the wave heading relative to the ship, as sailing in quartering waves (from 30 degrees off beam waves) yields much less green water than in beam waves. This suggests that a change in course can effectively mitigate the risk of experiencing large green water loads. Water depth was also found to have an important effect on green water loads, with the most frequent and largest loads being measured in the shallowest condition. However, its influence is only observed for wave heights above a given threshold. Differences were also noted between the two container arrangements on deck, however only in the loads originating from waves climbing on the hull after a slam had occurred.

A selection of the measured green water events throughout the campaign was further scrutinised using CFD and FEM analyses. MARIN’s CFD code COMFLOW is used to replicate the events numerically so that the wave-induced pressure distribution on the containers is obtained. The pressure distribution is then input into the FE model of a container stack (see Figure) to determine the deformation in time introduced by the load. By comparing the measured deformations and stresses in the different elements of the stacks with applicable criteria, MARIN could see whether there is going to be only limited damage or if a complete stack loss is likely.

Combined approach deploying model tests, CFD and FEM analysis

Green water belongs to the most complex hydrodynamic problems. Therefore, getting a grasp on the loads induced and understanding how containers stacked on deck will react required a specific approach, consisting of model tests in a wave basin and computations. In the first place, model tests were conducted to quantify the influence of freeboard height and the container arrangement on deck, wave characteristics and bathymetry on the frequency and amplitude of green water loads. To quantify the loads, the model was instrumented with several force panels spread over the side of the lowest containers on deck.

Snapshots of green water event in 4.5 m high beam waves (top) and 4.5 m high stern-quartering waves (bottom).

With the accident of the Ultra Large Container Ship “MSC Zoë” in January 2019, during which 342 containers were lost overboard a few miles off the Dutch Wadden Islands, the problem of recurring container losses and the associated pollution in an area labelled as “Particularly Sensitive Sea Area” regained public attention.

While the initial focus was on the larger vessels, more recent container losses from the 169 m “OOCL Rauma” and the 170 m “Baltic Tern” - representing five containers in both cases - showed that feeder ships are also at risk. With a relatively low freeboard, feeder ships are more vulnerable to green water than larger vessels. Therefore, the Dutch Ministry of Infrastructure and Water Management asked MARIN to conduct a study on the risk of green water exposure for feeder ships, in view of refining the recommendations sent by the Netherlands Coastguard to ships in the area.

Report