News

Shallow water

EEXI

Wind propulsion

Turbulent breakthrough

CFD VIM

Floating Wind

Shortsea shipping

Cover

J. de Kruif, "Autonomous docking of a feeder vessel; an experimental validation," in CAMS 2024, Blacksburg, USA, 2024 (submitted but not yet published).

B. J. de Kruif, "Autonomous docking of a feeder vessel," J. Mar. Sci. Technol, 2023 (accepted but not yet published).

December 2023, no. 138

B. J. de Kruif, "Applied trajectory generation to dock a feeder vessel," IFAC-PapersOnLine, vol. 55, no. 31, pp. 172-177, 2022.

Bibliograpy

E. F. G. van Daalen, G. Iavicoli, H. Cozijn, and B. J. de Kruif, "Simulation of a feeder on a port-to-port mission," in Oceans 2023, Limerick, Ireland, 2023.

MOSES

Create a MARIN account to stay updated

Report

Sustainable shortsea shipping gets a step closer through EU MOSES project

MARIN is a partner in the EU-funded project MOSES (AutoMated Vessels and Supply Chain Optimisation for Sustainable Short SEa Shipping). In this project, several innovations are being developed to improve container transport by shortsea shipping in European waters.

MARIN has designed an innovative container feeder vessel, including solutions for zero emission propulsion and autonomous operation.

The work of MARIN focussed on two ambitions. The first one is the ambition to reduce or eliminate harmful emissions by designing environmentally friendly vessels. And the second is the ambition to design an autonomous feeder vessel that can sail a large part of its route without human intervention.

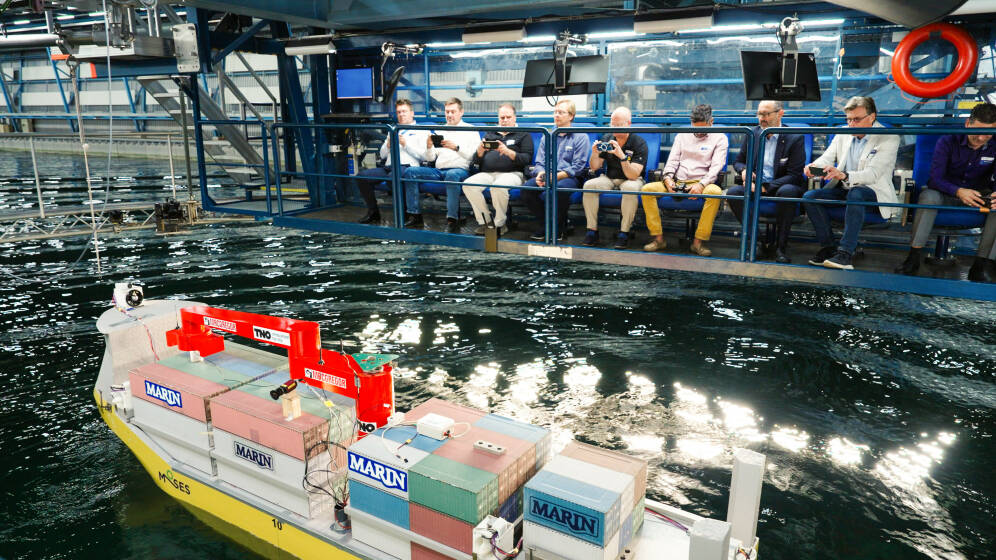

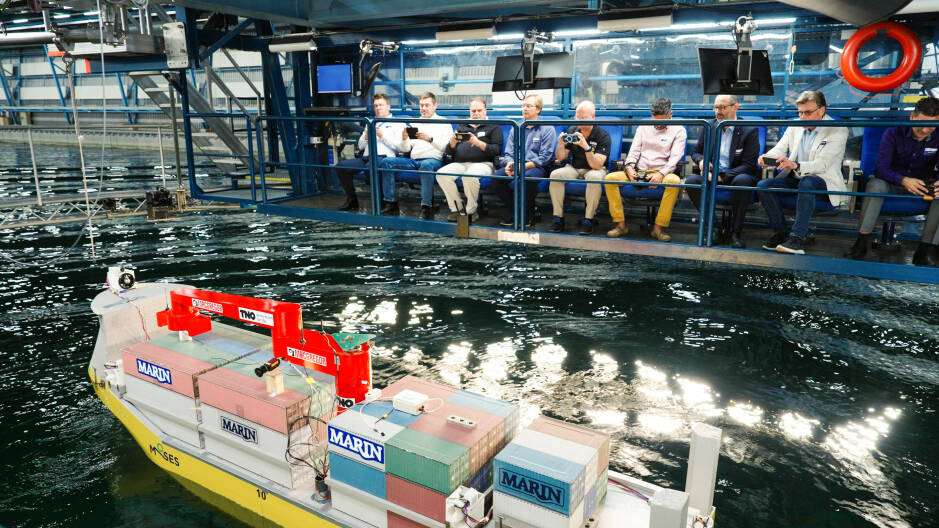

Autonomous sailing of the feeder vessel in the Seakeeping and Manoeuvring Basin.

Visitors in the model basin during the pilot demonstration.

Under the MOSES project, designs were made for two operational scenarios: one for Greece and one for Spain. The Spanish scenario has short routes around the port of Valencia, while the Greek scenario has a longer route from Piraeus to a number of Greek islands.

Zero emission design

With the first ship parameters, the route and cargo volumes, a so-called “trip simulation” is performed using MARIN’s Gulliver code. The outcome of these simulations provides input for the evaluation and selection of the different powering systems. In the process, 39 different powering systems were studied. Three of these options were selected and worked out in more detail in a general arrangement.

Demonstrating autonomous operation of a container feeder vessel in the Seakeeping and Manoeuvring Basin.

In the design of the vessels, future autonomous operations are already anticipated. This is done in the selection of the equipment, including an autonomous robotic crane (work by TNO and MacGregor), but also considering the effects autonomous operations might have on the potential safety of the vessels during sailing and while in port.

The design studies show that it is technically possible to design a solution with a methanol fuelled Internal Combustion Engine (ICE) or a hydrogen fuelled ICE in combination with a battery, or a full battery solution which enables part or full zero emission operations.

The MOSES project has received funding from the European Union’s Horizon 2020 research & innovation programme under grant agreement No. 861678.

The project scope includes the development of five innovations: the innovative feeder vessel, a robotic container handling system, the AutoDock system, a recharging station and a matchmaking platform. Pilot demonstrations were made for the feeder vessel, the robotic crane and the tugboat swarm for autonomous docking.

The MOSES consortium consists of 17 partners from seven European countries and the team is composed of system and automation designers (NTUA, MARIN, ASTANDER, CORE, ESI, TNO, DANAOS), maritime logistics and supply chain experts (SEABILITY and CIRCLE), technology platform providers (MacGregor, Trelleborg and TUCO), regulatory organisations (DNV), and stakeholders and end-users (SAT, Fundación Valenciaport, PCT, and MHM). NTUA is the project coordinator.

Scale model (1:17) of the innovative feeder vessel.

Pilot demonstration

Autonomous operations are demonstrated using a 1:17 scale model of the vessel in MARIN's Seakeeping and Manoeuvring Basin. The scale model sails completely wirelessly, with its own power supply. Software to control the vessel is installed on an onboard computer, while measured signals are transferred to the basin carriage using a Wi-Fi connection. The model is able to perform a round-trip through the basin, including autonomous docking and undocking. Using a remote operator interface, which is on the basin carriage, the operation can be started and stopped. After starting the trip, the vessel can execute the complete round-trip without any external instructions. For visual purposes, a dummy container crane is placed on the scale model. The automated operation of a real container crane is demonstrated by TNO and MacGregor in another pilot demonstration in the MOSES project.

Besides the basin demonstration in the afternoon, the day included a morning programme of technical presentations. Furthermore, information booths about related projects were present at the basin demonstration.

Autonomous operation

The autonomous operation of the Greek innovative feeder vessel is investigated using a two-step approach. First, a time-domain simulation model of the ship is made and algorithms for vehicle control and autonomous operation are designed, implemented and tested. Secondly, the simulation model is replaced by a physical scale model and the software for autonomous control is used to demonstrate autonomous vessel operations in the model basin.

More info

Create a MARIN account to stay updated

J. de Kruif, "Autonomous docking of a feeder vessel; an experimental validation," in CAMS 2024, Blacksburg, USA, 2024 (submitted but not yet published).

B. J. de Kruif, "Autonomous docking of a feeder vessel," J. Mar. Sci. Technol, 2023 (accepted but not yet published).

B. J. de Kruif, "Applied trajectory generation to dock a feeder vessel," IFAC-PapersOnLine, vol. 55, no. 31, pp. 172-177, 2022.

Bibliograpy

E. F. G. van Daalen, G. Iavicoli, H. Cozijn, and B. J. de Kruif, "Simulation of a feeder on a port-to-port mission," in Oceans 2023, Limerick, Ireland, 2023.

Demonstrating autonomous operation of a container feeder vessel in the Seakeeping and Manoeuvring Basin.

Scale model (1:17) of the innovative feeder vessel.

December 2023,

no. 138

MOSES

The MOSES project has received funding from the European Union’s Horizon 2020 research & innovation programme under grant agreement No. 861678.

The project scope includes the development of five innovations: the innovative feeder vessel, a robotic container handling system, the AutoDock system, a recharging station and a matchmaking platform. Pilot demonstrations were made for the feeder vessel, the robotic crane and the tugboat swarm for autonomous docking.

The MOSES consortium consists of 17 partners from seven European countries and the team is composed of system and automation designers (NTUA, MARIN, ASTANDER, CORE, ESI, TNO, DANAOS), maritime logistics and supply chain experts (SEABILITY and CIRCLE), technology platform providers (MacGregor, Trelleborg and TUCO), regulatory organisations (DNV), and stakeholders and end-users (SAT, Fundación Valenciaport, PCT, and MHM). NTUA is the project coordinator.

Pilot demonstration

Autonomous operations are demonstrated using a 1:17 scale model of the vessel in MARIN's Seakeeping and Manoeuvring Basin. The scale model sails completely wirelessly, with its own power supply. Software to control the vessel is installed on an onboard computer, while measured signals are transferred to the basin carriage using a Wi-Fi connection. The model is able to perform a round-trip through the basin, including autonomous docking and undocking. Using a remote operator interface, which is on the basin carriage, the operation can be started and stopped. After starting the trip, the vessel can execute the complete round-trip without any external instructions. For visual purposes, a dummy container crane is placed on the scale model. The automated operation of a real container crane is demonstrated by TNO and MacGregor in another pilot demonstration in the MOSES project.

Besides the basin demonstration in the afternoon, the day included a morning programme of technical presentations. Furthermore, information booths about related projects were present at the basin demonstration.

Autonomous operation

The autonomous operation of the Greek innovative feeder vessel is investigated using a two-step approach. First, a time-domain simulation model of the ship is made and algorithms for vehicle control and autonomous operation are designed, implemented and tested. Secondly, the simulation model is replaced by a physical scale model and the software for autonomous control is used to demonstrate autonomous vessel operations in the model basin.

In the design of the vessels, future autonomous operations are already anticipated. This is done in the selection of the equipment, including an autonomous robotic crane (work by TNO and MacGregor), but also considering the effects autonomous operations might have on the potential safety of the vessels during sailing and while in port.

The design studies show that it is technically possible to design a solution with a methanol fuelled Internal Combustion Engine (ICE) or a hydrogen fuelled ICE in combination with a battery, or a full battery solution which enables part or full zero emission operations.

Zero emission design

With the first ship parameters, the route and cargo volumes, a so-called “trip simulation” is performed using MARIN’s Gulliver code. The outcome of these simulations provides input for the evaluation and selection of the different powering systems. In the process, 39 different powering systems were studied. Three of these options were selected and worked out in more detail in a general arrangement.

Autonomous sailing of the feeder vessel in the Seakeeping and Manoeuvring Basin.

Visitors in the model basin during the pilot demonstration.

Under the MOSES project, designs were made for two operational scenarios: one for Greece and one for Spain. The Spanish scenario has short routes around the port of Valencia, while the Greek scenario has a longer route from Piraeus to a number of Greek islands.

MARIN has designed an innovative container feeder vessel, including solutions for zero emission propulsion and autonomous operation.

The work of MARIN focussed on two ambitions. The first one is the ambition to reduce or eliminate harmful emissions by designing environmentally friendly vessels. And the second is the ambition to design an autonomous feeder vessel that can sail a large part of its route without human intervention.

MARIN is a partner in the EU-funded project MOSES (AutoMated Vessels and Supply Chain Optimisation for Sustainable Short SEa Shipping). In this project, several innovations are being developed to improve container transport by shortsea shipping in European waters.

Sustainable shortsea shipping gets a step closer through EU MOSES project

Report