News

Carbon Collectors

Bubble curtains

Floating wind

Wind statistics

Operational advice

Floating Future

Crabbing

Cover

More info

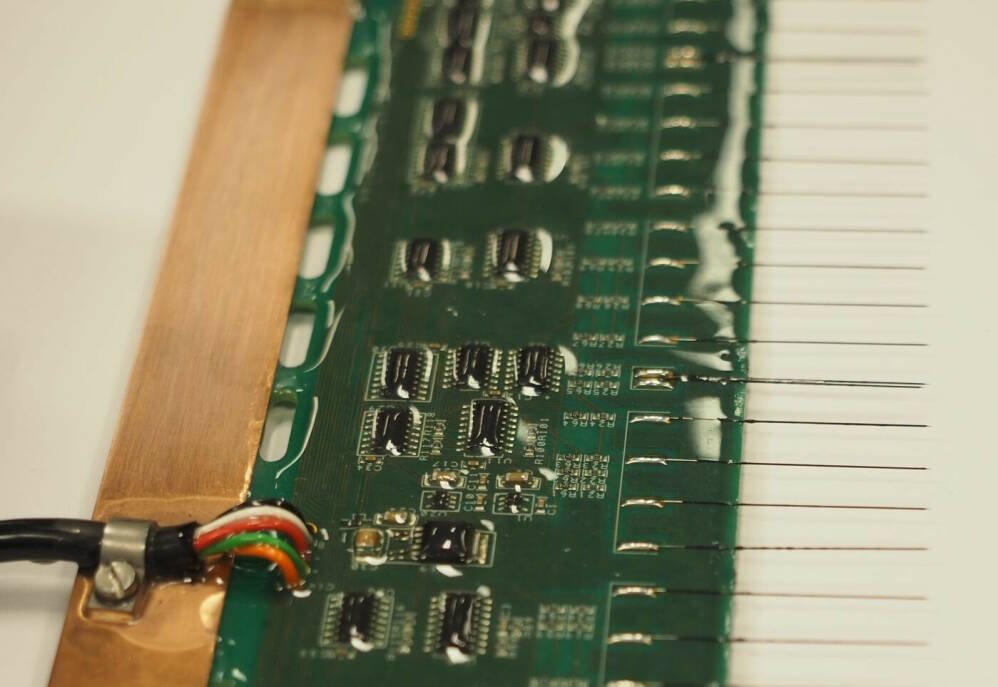

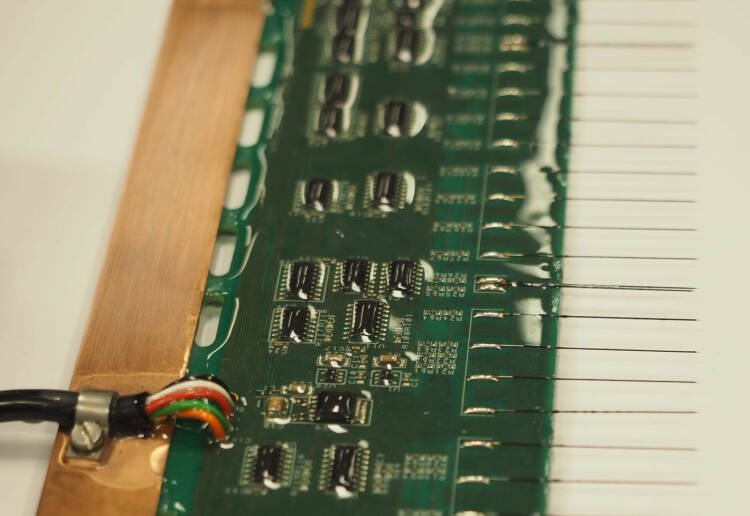

Figure 2. PCB with needles, electronics and cable.

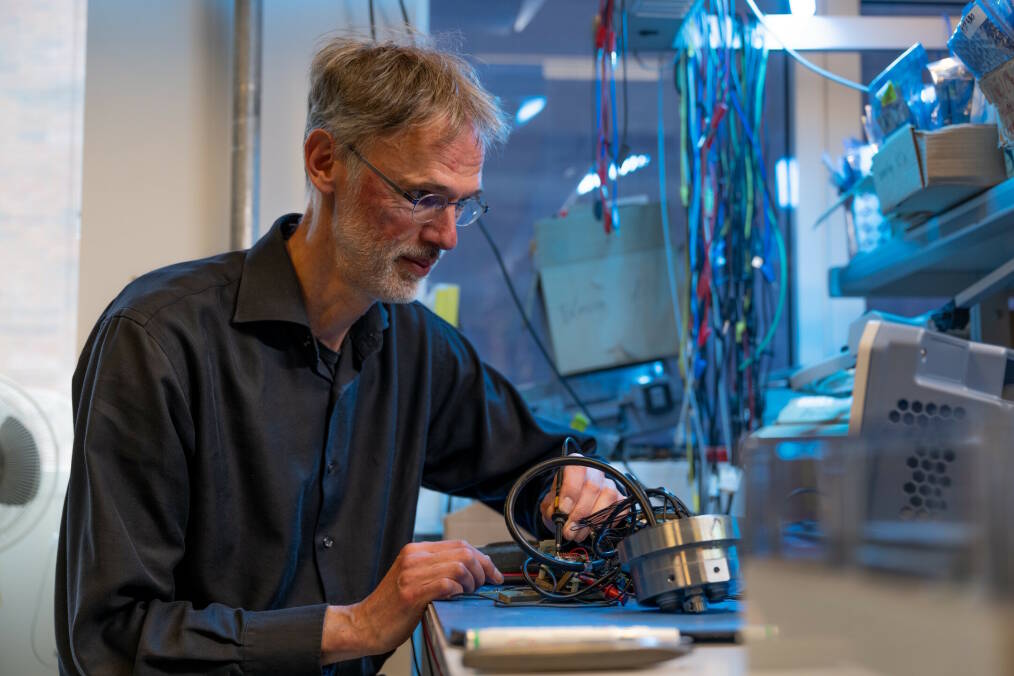

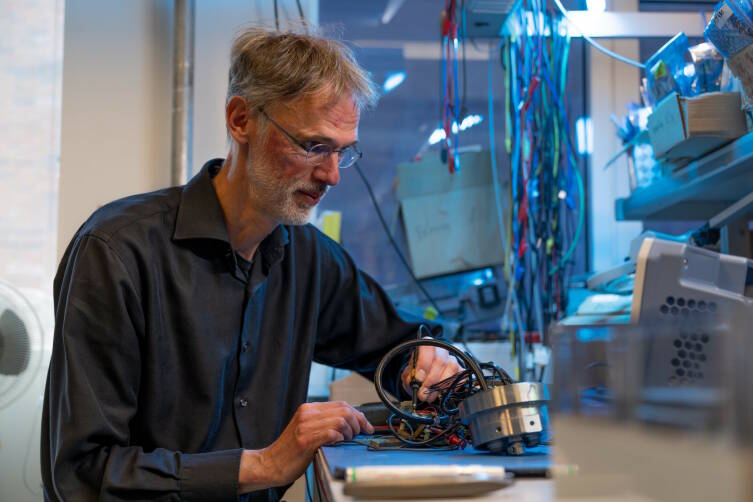

Fedde Bloemhof, Measurement Techniques Specialist explains more about the project.

October 2023, no. 137

Create a MARIN account to stay updated

Report

As the Bubbles JIP successfully concludes, fresh insight has been gained into the understanding of bubble curtains. But given the complex engineering involved, a follow-up JIP is being established.

A consortium of research institutes and industry partners involved in the offshore wind sector set up the Bubbles JIP initiative in 2019. The aim was to achieve more efficient and effective use of bubble curtains deployed for noise mitigation in offshore installation projects by improved engineering of the bubble screen.

During installation of monopiles and jackets at sea, the noise generated by high-energy piling may harm the marine environment. To mitigate the risk of noise for marine life, limits are included in permits for pile driving operations for offshore construction projects.

Bubble curtain in the Offshore Basin (Image GROW)

A looped hose on the seabed - pressurised by air compressors – generates the bubble curtain. Currently, bubble curtain designs are largely based on previous experience, taking into account the complex behaviour of bubbles underwater. However, companies experience large variations in the current performance of bubble curtains. Therefore, the JIP wanted to have an improved understanding of the noise generation and mitigation mechanisms, enabling better engineering of the bubble curtains, leading to screens that are more effective and less expensive. Enhanced screens will also reduce the risk of not complying with the specific noise requirements of the piling project.

Figure 1. left: conduction; right: isolation.

isolated shaft

bare tip

air

air

water

How to measure masses of bubbles?

Fedde Bloemhof: “For a more detailed understanding of multiphase flows applied for air lubrication and bubble curtains for example, we wanted to gather statistics of the bubbles in these flows. This has been done before by various institutes, but never on the scale we had in mind. We needed a lot of measurements, spread in both time and space, to get a complete image of a bubble curtain.

One of the measurement techniques makes use of the electrical conductivity of water and the fact that air is a good insulator. To measure conductivity, we need a plus and a minus pole. So we applied a large minus in the water and connected the plus to a small metal tip. An electrical current flows when the tip is surrounded by water and the current is blocked when the tip is surrounded by an air bubble (Figure 1). To measure small bubbles, the needle tip needs to be small. We use 0.3mm stainless steel needles, originally made for acupuncture therapy. Only the tip is free and the shaft of the needle is carefully coated to avoid unwanted current flow through any part but the tip.

But we have to deal with two challenges: first, the corrosion caused by a steady current in a liquid. We solved this problem by applying alternating current: the corrosion arising in the first cycle is dissolved in the second when the current flows in the opposite direction.

The second challenge was the sheer scale: 120 or 240 needles, cleverly distributed over the area of interest. Was it possible to accurately place and connect each needle and connect them error-free (and free of electrical leaks) to the MARIN measurement system? Not to mention the huge amount of resources needed for a measurement campaign with 240 channels! We designed a simple circuit that measures the presence or absence of current while using an alternating current. This simple circuit allowed us to combine all efforts on one (coated) printed circuit board (Figure 2): the needle, the measurement circuit and a serialisation unit that compresses all the data in one or two cables. So, simplicity solved most of our challenges. The drive and dedication of our instrumentation engineers did the rest.”

Fedde Bloemhof

As a result, the partners are investigating the continuation of the project and performing a more in-depth study which could result in tests offshore to capture all the physics, effects and environmental impact.

The Bubbles JIP is supported by the Netherlands Enterprise Agency (RVO) and TKI Wind op Zee and is an initiative of GROW which is a joint research programme in the offshore wind sector that performs research and accelerates innovations. Consortium members are Boskalis, IHC, Seaway Heavy Lifting, TNO, TU Delft, Van Oord, Heerema Marine Contractors, Wageningen Marine Research and MARIN.

In combination with numerical models, laboratory and medium-scale tests, more knowledge about bubble curtain development over the water depth and bubble curtain noise reduction mechanisms was obtained. Furthermore, the tests provided validation material for the numerical models.

Best practice

The main findings, lessons learned, and recommendations to improve the working of the bubble screens were collected in a first draft of a best practice document. Furthermore, the partners concluded that the topic was more complex than previously expected and additional research is required to fully understand the physics of a bubble curtain on the seabed

Figure 2. PCB with needles, electronics and cable.

Fedde Bloemhof, Measurement Techniques Specialist explains more about the project.

More info

Figure 1. left: conduction; right: isolation.

isolated shaft

bare tip

air

air

water

How to measure masses of bubbles?

Fedde Bloemhof: “For a more detailed understanding of multiphase flows applied for air lubrication and bubble curtains for example, we wanted to gather statistics of the bubbles in these flows. This has been done before by various institutes, but never on the scale we had in mind. We needed a lot of measurements, spread in both time and space, to get a complete image of a bubble curtain.

One of the measurement techniques makes use of the electrical conductivity of water and the fact that air is a good insulator. To measure conductivity, we need a plus and a minus pole. So we applied a large minus in the water and connected the plus to a small metal tip. An electrical current flows when the tip is surrounded by water and the current is blocked when the tip is surrounded by an air bubble (Figure 1). To measure small bubbles, the needle tip needs to be small. We use 0.3mm stainless steel needles, originally made for acupuncture therapy. Only the tip is free and the shaft of the needle is carefully coated to avoid unwanted current flow through any part but the tip.

But we have to deal with two challenges: first, the corrosion caused by a steady current in a liquid. We solved this problem by applying alternating current: the corrosion arising in the first cycle is dissolved in the second when the current flows in the opposite direction.

The second challenge was the sheer scale: 120 or 240 needles, cleverly distributed over the area of interest. Was it possible to accurately place and connect each needle and connect them error-free (and free of electrical leaks) to the MARIN measurement system? Not to mention the huge amount of resources needed for a measurement campaign with 240 channels! We designed a simple circuit that measures the presence or absence of current while using an alternating current. This simple circuit allowed us to combine all efforts on one (coated) printed circuit board (Figure 2): the needle, the measurement circuit and a serialisation unit that compresses all the data in one or two cables. So, simplicity solved most of our challenges. The drive and dedication of our instrumentation engineers did the rest.”

As a result, the partners are investigating the continuation of the project and performing a more in-depth study which could result in tests offshore to capture all the physics, effects and environmental impact.

The Bubbles JIP is supported by the Netherlands Enterprise Agency (RVO) and TKI Wind op Zee and is an initiative of GROW which is a joint research programme in the offshore wind sector that performs research and accelerates innovations. Consortium members are Boskalis, IHC, Seaway Heavy Lifting, TNO, TU Delft, Van Oord, Heerema Marine Contractors, Wageningen Marine Research and MARIN.

Fedde Bloemhof

In combination with numerical models, laboratory and medium-scale tests, more knowledge about bubble curtain development over the water depth and bubble curtain noise reduction mechanisms was obtained. Furthermore, the tests provided validation material for the numerical models.

Best practice

The main findings, lessons learned, and recommendations to improve the working of the bubble screens were collected in a first draft of a best practice document. Furthermore, the partners concluded that the topic was more complex than previously expected and additional research is required to fully understand the physics of a bubble curtain on the seabed

A looped hose on the seabed - pressurised by air compressors – generates the bubble curtain. Currently, bubble curtain designs are largely based on previous experience, taking into account the complex behaviour of bubbles underwater. However, companies experience large variations in the current performance of bubble curtains. Therefore, the JIP wanted to have an improved understanding of the noise generation and mitigation mechanisms, enabling better engineering of the bubble curtains, leading to screens that are more effective and less expensive. Enhanced screens will also reduce the risk of not complying with the specific noise requirements of the piling project.

Bubble curtain in the Offshore Basin (Image GROW)

A consortium of research institutes and industry partners involved in the offshore wind sector set up the Bubbles JIP initiative in 2019. The aim was to achieve more efficient and effective use of bubble curtains deployed for noise mitigation in offshore installation projects by improved engineering of the bubble screen.

During installation of monopiles and jackets at sea, the noise generated by high-energy piling may harm the marine environment. To mitigate the risk of noise for marine life, limits are included in permits for pile driving operations for offshore construction projects.

As the Bubbles JIP successfully concludes, fresh insight has been gained into the understanding of bubble curtains. But given the complex engineering involved, a follow-up JIP is being established.

October2023, no. 137

Report