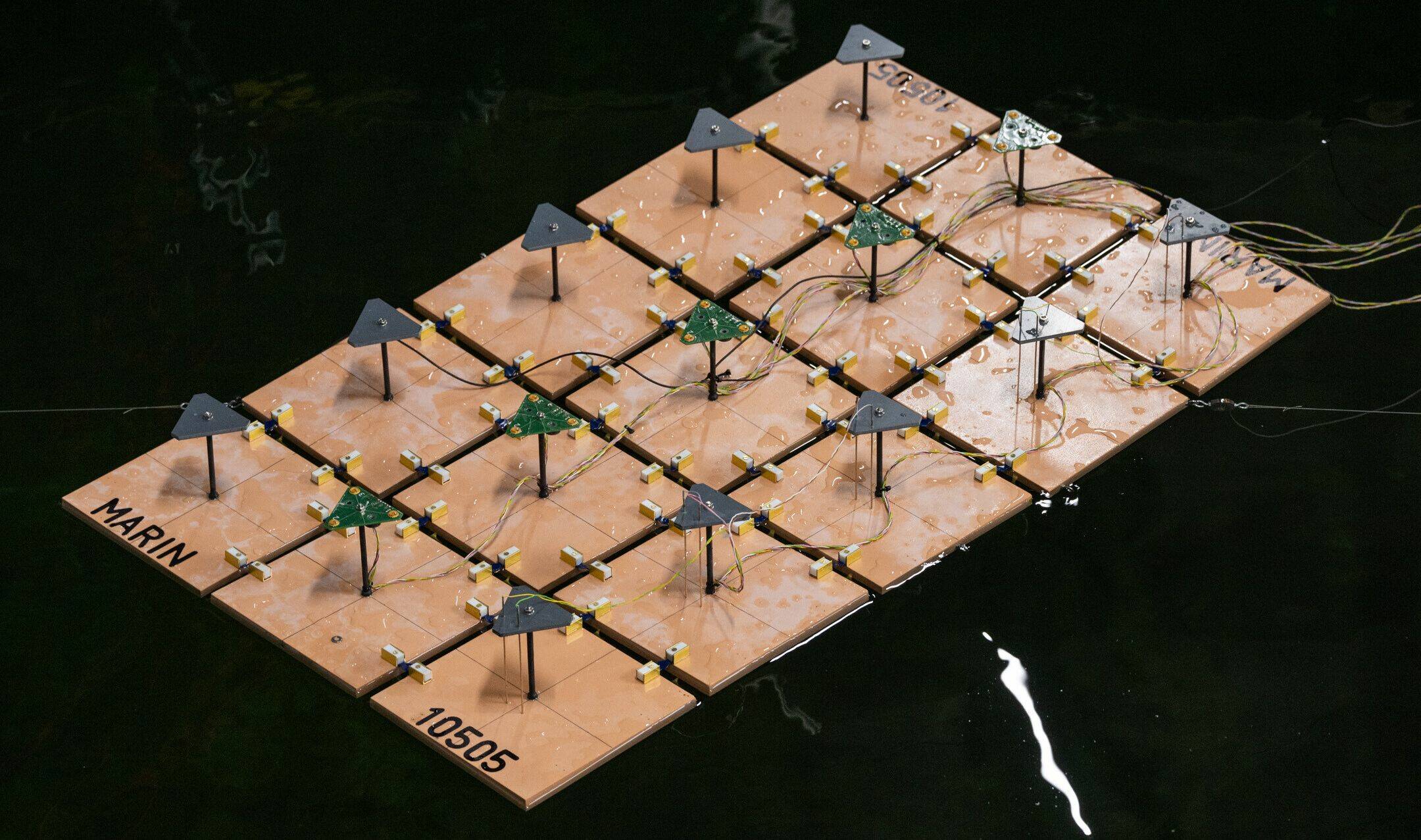

Floating PV model installed in the basin.

March 2024, no. 139

Create a MARIN account to stay updated

Motions of a 100-module floating PV system calculated using the wave diffraction solver DIFFRAC.

SUREWAVE consortium visits the basin tests.

Report

Wave basin tests to demonstrate an integrated floating breakwater and solar farm concept

The Horizon Europe project SUREWAVE (2022-2025) aims to develop a floating solar farm for offshore environments.

“The wave tank experiments are essential to ensure that our design and the numerical models represent the real-life behaviour.”

Balram Panjwani

“Having all the consortium partners attending the basin tests at MARIN is crucial for the collective observation and the interpretation of results.”

Balram Panjwani,

Project Coordinator SUREWAVE

A year into the project, an early-stage design was tested at 1:10 scale in MARIN’s Concept Basin. In order to ensure the same motion response at protype and model scale for all degrees of freedom, particular effort was put into the scaling of the elastic joints that interconnect the PV modules. In general, the geometry and inertial properties of the design are scaled from the prototype in wave basin tests. For the present floating PV system, scaling laws should also be applied to the elastic properties of the PV joints. Therefore, firstly, the elasticity of the prototype hinges was quantified through tensile testing. Subsequently, a polyurethane material with reduced elasticity (factor 10) was selected to produce model scale hinges with the appropriate stiffness properties in all degrees of freedom.

The multi-disciplinary consortium was invited to the tests at MARIN, which also enabled non-hydrodynamic experts to obtain insights into the integrated system’s performance (video above). The next steps in the project involve the design of a surface and bottom mooring layout, the further improvement of the design of PV module interconnectors, and the analysis of the durability of materials due to fatigue loading. MARIN will support these steps through diffraction calculations and time domain simulations (video below), which are presently being validated using the basin test data.

A fifteen-module version of the floating PV system was tested in mild and harsh environments, both with and without the sheltering effect of an external floating breakwater. The tests focused on the relative motions between panels, which determine the loads on the joints. Results indicate that the joints near the middle of the assembled PV system experience the largest axial loads, while the shear loads are highest for the joints connecting the outward modules. The relative motions between modules, hence the loads on the joints, are governed by excitation at high wave frequencies. Because the floating breakwater is particularly effective in this high-frequency regime, the tests with the breakwater demonstrated a substantial reduction in relative motions and reduced the buckling of the joints that interconnect the PV modules. Furthermore, the breakwater reduced the wave overwash (green water) over the PV modules.

An existing design of interconnected photovoltaic (PV) modules is being integrated with an external floating breakwater in the EU project.

The SUREWAVE consortium includes floating breakwater and PV developers, material and hydrodynamic specialists, and lifecycle assessment experts. MARIN’s contribution involves numerical simulations and basin tests to quantify and improve the system’s hydrodynamic behaviour.

More info

marin.nl/jips/

surewave

Joep van der Zanden

Senior Project Manager Offshore

Motions of a 100-module floating PV system calculated using the wave diffraction solver DIFFRAC.

“The wave tank experiments are essential to ensure that our design and the numerical models represent the real-life behaviour.”

Balram Panjwani

marin.nl/jips/

surewave

A fifteen-module version of the floating PV system was tested in mild and harsh environments, both with and without the sheltering effect of an external floating breakwater. The tests focused on the relative motions between panels, which determine the loads on the joints. Results indicate that the joints near the middle of the assembled PV system experience the largest axial loads, while the shear loads are highest for the joints connecting the outward modules. The relative motions between modules, hence the loads on the joints, are governed by excitation at high wave frequencies. Because the floating breakwater is particularly effective in this high-frequency regime, the tests with the breakwater demonstrated a substantial reduction in relative motions and reduced the buckling of the joints that interconnect the PV modules. Furthermore, the breakwater reduced the wave overwash (green water) over the PV modules.

SUREWAVE consortium visits the basin tests.

The multi-disciplinary consortium was invited to the tests at MARIN, which also enabled non-hydrodynamic experts to obtain insights into the integrated system’s performance (video above). The next steps in the project involve the design of a surface and bottom mooring layout, the further improvement of the design of PV module interconnectors, and the analysis of the durability of materials due to fatigue loading. MARIN will support these steps through diffraction calculations and time domain simulations (video below), which are presently being validated using the basin test data.

“Having all the consortium partners attending the basin tests at MARIN is crucial for the collective observation and the interpretation of results.”

Balram Panjwani,

Project Coordinator SUREWAVE

A year into the project, an early-stage design was tested at 1:10 scale in MARIN’s Concept Basin. In order to ensure the same motion response at protype and model scale for all degrees of freedom, particular effort was put into the scaling of the elastic joints that interconnect the PV modules. In general, the geometry and inertial properties of the design are scaled from the prototype in wave basin tests. For the present floating PV system, scaling laws should also be applied to the elastic properties of the PV joints. Therefore, firstly, the elasticity of the prototype hinges was quantified through tensile testing. Subsequently, a polyurethane material with reduced elasticity (factor 10) was selected to produce model scale hinges with the appropriate stiffness properties in all degrees of freedom.

An existing design of interconnected photovoltaic (PV) modules is being integrated with an external floating breakwater in the EU project.

The SUREWAVE consortium includes floating breakwater and PV developers, material and hydrodynamic specialists, and lifecycle assessment experts. MARIN’s contribution involves numerical simulations and basin tests to quantify and improve the system’s hydrodynamic behaviour.

March 2024, no. 139

More info

Wave basin tests to demonstrate an integrated floating breakwater and solar farm concept

Create a MARIN account to stay updated

The Horizon Europe project SUREWAVE (2022-2025) aims to develop a floating solar farm for offshore environments.

Report